Optimizing EWIS and Harness Integration with Tool-Less Multipin Connector Technologies

Electrical Wiring Interconnection Systems (EWIS) are the backbone of aerospace and defense platforms, connecting complex networks of signals and power. Modern aircraft and military vehicles demand lighter, more compact harnesses with higher signal density to accommodate advanced systems and reduce weight. These requirements create challenges for traditional connector technologies that rely on tools for assembly and maintenance.

As harness complexity increases, the risk of installation errors and time-consuming maintenance grows. Engineers face pressure to reduce assembly time while maintaining reliability under harsh environmental conditions. The need for innovative connector solutions that simplify integration without compromising performance is more critical than ever.

Benefits of Tool-Less Multipin Connector Technologies

Tool-less multipin connectors provide significant advantages over traditional connectors by reducing assembly and maintenance time. With push-pull mating and modular designs, these connectors minimize human error and simplify harness installation; allowing technicians to work efficiently even in confined spaces.

These technologies also improve reliability and repeatability, ensuring consistent performance across multiple installations. They enable flexible design changes or upgrades without requiring extensive rework. For industries where downtime is costly, tool-less connectors offer a clear operational advantage.

Radiall Product Solutions and Applications

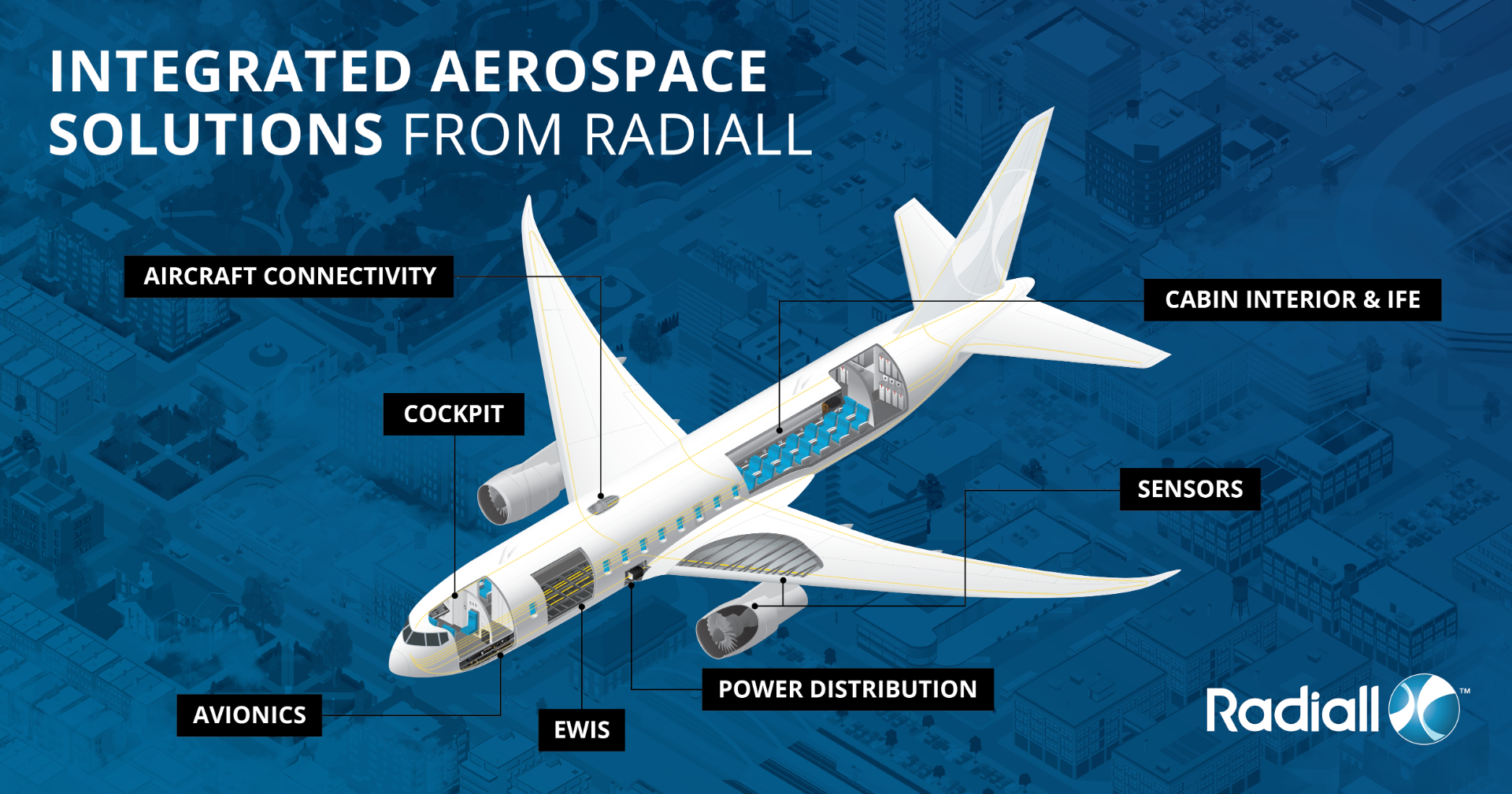

Radiall offers a broad portfolio of multipin connector technologies purpose-built for EWIS and harness integration challenges. Exclusive products such as the Quick Install Radiall (QR) series provide tool‑less panel mounting and quick mating that can cut installation time dramatically and simplify maintenance with visual indicators and push‑to‑mate design. The EPX™ – EN4644 family delivers modular, high‑density rectangular solutions that support rapid harness integration for both signal and power, while DSX‑ARINC 404 & SAE AS 81659 connectors offer rugged, compact interfaces for sensors, avionics and cabin systems requiring quick, reliable connections.

In real‑world aerospace and defense applications, Radiall’s connectors have helped streamline complex harness assemblies and reduce common wiring errors. For example, manufacturers using Quick Install Radiall connectors have seen significant reductions in installation and field maintenance time compared with legacy screwed connectors, while EPX™ and DSX families support robust signal integrity and environmental performance across harsh conditions. These products demonstrate measurable gains in productivity, reliability and long‑term system efficiency in modern EWIS designs.

Best Practices for Integrating Tool-Less Connectors into EWIS

Successful integration begins with careful consideration of wire gauge compatibility, signal requirements, and environmental conditions. Engineers should plan connector placement and orientation to optimize space and ensure accessibility for assembly and maintenance.

During installation, proper sequencing and handling prevent damage and ensure consistent performance. The tool-less design, allowing rapid replacement or reconfiguration of components, simplifies regular maintenance. As systems evolve, these connectors support future-ready harness designs and pave the way for digital integration and smart wiring solutions.